冷房について①

ー気化冷却による冷房ー

ハウス 高温対策

目次

ハウスの高温対策として、換気の他、外部からの熱の侵入を抑える遮光や遮熱、強制的に温度を低下させる冷房といった方法があります。また冷房には気化冷却による方法やヒートポンプを利用する方法があります。本記事では、気化冷却による冷房についてご紹介します。

(1)気化冷却とは

気化冷却とは、水が水蒸気になる際に気化熱(水1リットル当たり約2,400kJ)が必要なことから、水を水蒸気に変化させることにより気温を低下させる方法のことです。植物は根から水分を吸収し、気孔より水蒸気を放出しています。これは蒸散と呼ばれるもので、その際にも気化冷却効果が生じています。また密植などにより作物の葉数や葉面積を確保し、蒸散を促すことでの気化冷却効果もあります。これは最も費用がかからず、シンプルな冷却方法と言えるでしょう(条件によります)。

(2)ミストによる冷房(細霧冷房)

前述の作物の蒸散による水蒸気の放出に対し、人為的にミスト(微細な水滴、細霧とも呼ぶ)を空中に放出して蒸発を促し気化冷却効果を狙う方法があります。これを気化冷却法、細霧冷房などと呼んでいます。

細霧冷房の原理と方法

細霧冷房ではハウス内にミストを放出して、その蒸発による気化冷却効果で冷房を行います。その際に相対湿度も上昇しミストの蒸発も抑制されます。一方でハウス内が乾燥し相対湿度も低ければ、ミストの蒸発は促進されます。またハウスが密閉状態で細霧冷房を行うと、相対湿度は100%まで上昇し、ミストの蒸発は困難になります。そのため通常は換気を行いながら相対湿度の上昇もある程度抑制し、細霧冷房は行われています。

細霧冷房では、ミストノズルと呼ばれる器具に高圧で水を送り、粒径の小さいミストとして空気中に放出させます。そのため動力噴霧器(動噴)と高圧に耐えうる金属等の配管設備が必要になります。細霧冷房で必要な機器資材類はこれらのものが中心で、その他に温湿度などに応じて動噴等の動作を制御する制御装置類が必要になります。

なお夜間は日射が無く、気化冷却も期待できないため、夜間冷房用に細霧冷房を行うことは難しいと考えられます。夜間にはヒートポンプにより冷風を発生させることでの直接的な冷房が効果を生むものと考えられます。

ミストと細霧冷房の効果

ミストの粒径が小さければ(おおむね30~50ミクロン程度)蒸発もしやすく、気化冷却による細霧冷房の効果も期待できます。また粒径が大きければミストが蒸発せずに水滴として地面や作物に付着することも起こりえます。粒径の小さいミストを放出できるノズルは高価であり、またそのための動噴の能力も必要になり、細霧冷房装置全体のコストも上昇します。しかし安価なノズルを用いると粒径の大きなミストしか発生せず、気化冷却効果も低くなる場合があり注意が必要です。

細霧冷房における制御方法

ミスト噴霧には冷房目的の場合と単純な加湿目的の二つのケースが考えられます。そのため制御の方法によって、これらの目的を選択することになります。

冷房目的の場合には、目標温度以上になった場合に細霧冷房装置を稼働(動噴や電磁弁をONにしてミストを噴霧させる動作のこと)させ、目標温度以下になった場合には停止させることが、最もシンプルな制御方法になります。一方で温度のみを制御対象とした場合には加湿状態となった場合に温度低下が起こりにくくなるため、ミストの噴霧が続き更に加湿状態になることも予想されます。そのため。温度とともに相対湿度も制御要素に組み込む場合もありますが、一般的にはサブタイマーを利用してミスト噴霧を間欠運転させる方法が取られています。ここでは間欠動作により、過剰な噴霧を防止することになります。

また日射量も制御に組み込み、遮光カーテンの展張も行いながら細霧冷房を行うなど、より複雑な制御を行うケースもみられます。このように様々な制御方法や制御要因を組み込むことが考えられ、その動作や効果については一つ一つ確認、検証する必要もあるでしょう。

加湿目的の場合は、シンプルに相対湿度や飽差を目標設定値として、上限下限の設定値に対して動作と停止を行う制御方法が考えられます。

(3)強制換気と組み合わせた気化冷却

強制換気と細霧冷房の組み合わせ

前述の細霧冷房では、換気による加湿防止とミストの気化促進が必要になりますが、多くの場合は天窓や側窓などの自然換気との併用によるものです。一方で大型の換気扇による強制換気を行って比較的乾燥した外気を室内に導入し細霧冷房を行う方法もみられます。この場合の気化冷却効果は自然換気の場合に比べて高いものが期待されます。また強制換気ではありませんが、ハウス内の循環扇に直接ノズルを取り付け、循環扇による通風を行いながらミスト噴霧を行う場合もあります。

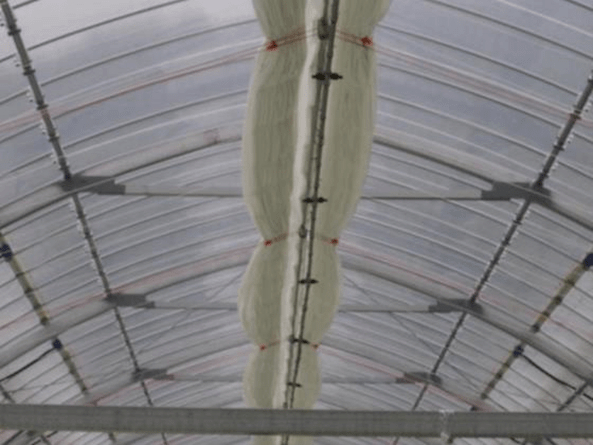

パッド&ファンによる気化冷却

細霧冷房ほど一般的ではありませんが、強制換気と気化冷却を組み合わせた冷房としてパッド&ファンがあります。これは大型換気扇による排気を行いながら、吸気側に取り付けたパッドに水を滴下させ、そこでの気化冷却を通風により促進し、室内に冷却された外気を取り込むものです。パッドとは波状のセルロースの紙を複層に加工したもので、上部から水滴を落とすとパッド全体に水滴が行きわたり蒸発する構造となっています。

セルロースの紙を波状・複層に加工したもので、上部より水滴を垂らし冷風を発生させる

ミストを空中に噴霧するのではなく、あくまで水滴のまま蒸発させる方式のため、ハウス内が加湿状態になることも少なく、マイルドな冷房方式と言えるかもしれません。一方で換気扇により発生する気流の片側の端部のみで気化冷却が行われるため、ハウス内に温度勾配が発生し、排気側(ファン)の温度は吸気側(パッド)の温度よりも高くなります。そのためその間の距離が長い場合には実用性が低下するため注意が必要です。

(4)自家施工について

上述のパッド&ファンは、パッドの施工費が負担となる場合もあり、代用品による自家施工を行うケースもみられます。文献2)ではパッドのかわりに市販の寒冷紗を展張し、散水パイプで井戸水を散布する方法を紹介しています。また耐久性のある市販のキッチンペーパーをパッドの代用品として使うケースもあるようです。

また前述の細霧冷房でも、粒径の小さなミストを噴霧可能な外国製の安価なノズルも一部で使われており、それらを配管に自家施工で取り付けるケースもあるようです。このような形で、できる範囲での自家施工を行って、導入コストの低減をはかることも考えられます。

今後の展開

気化冷却以外の冷房にはヒートポンプの利用があります。これは初期コストやランニングコスト(電気代)が大きいこと、日射のある昼間の冷房には向かないこと(夜間冷房が中心)などのデメリットがあります。昼間の冷房を積極的に行うには、気化冷却によるものが一般的、かつ実用的であると考えられ、一層の導入コスト低減には前述のような自家施工を取り入れる例も今後は増えることも考えられます。

参考文献

- 林真紀夫、冷房ー地上部環境制御、農業技術体系<追録第3号・2001年>第3巻

- 自作パッド&ファンで夏バラの秀品率が6割超、現代農業2014年8月

■執筆者:農業技術士 土屋 和(つちや かずお)

育苗装置「苗テラス」の開発など農業資材業界での経験を活かし国家資格の技術士(農業部門)を2008年に取得、近年は全国の施設園芸の調査や支援活動、専門書等の執筆を行っています。